The Value of Quality in the Production of Copper Products

The significance of top quality in the manufacturing of copper items extends much past simple compliance; it is essential to maximizing performance across different sectors. Premium copper not just enhances conductivity but likewise guarantees resilience and dependability, which are essential in applications ranging from electronic devices to auto systems. However, the ramifications of bad production methods can reverberate with prices and safety standards, ultimately impacting consumer depend on. As we check out the complex nature of high quality, the concern emerges: exactly how can makers stabilize these obstacles to accomplish excellence?

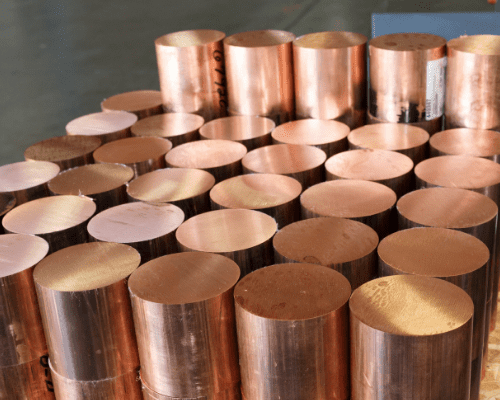

Influence On Product Performance

The high quality of copper products plays an essential duty in determining their general efficiency in different applications. Top notch copper exhibits exceptional electrical conductivity, thermal conductivity, and rust resistance, which are essential qualities for markets such as electronic devices, construction, and auto.

Moreover, the mechanical buildings of copper, consisting of ductility and tensile toughness, considerably influence its performance in making processes. Copper products that fulfill strict high quality standards can hold up against substantial stress and anxiety without flawing, consequently improving longevity and reducing the probability of failing sought after atmospheres.

Additionally, the surface coating of copper products impacts their efficiency. A smooth, well-treated surface area can stop oxidation and other types of deterioration, ultimately lengthening the life of the component. In summary, the high quality of copper items directly affects their functionality, reliability, and longevity across numerous fields, making it important for producers to abide by rigorous high quality control procedures throughout the production procedure.

Expense Effects mediocre

Purchasing high-quality copper products is crucial, as the price implications mediocre can be substantial for end-users and suppliers alike. Poor high quality copper can lead to enhanced failing rates, leading to expensive repairs and substitutes. Manufacturers might encounter substantial downtime as malfunctioning items demand recalls or remodel, disrupting manufacturing timetables and impacting overall efficiency.

From an end-user perspective, the effects are equally extreme. Poor-quality copper can lead to inadequacies and raised operational costs, as devices might call for even more constant upkeep. Ultimately, the preliminary savings obtained from selecting lower-quality copper items can be outweighed by these long-term expenses, making the search of high quality not simply a matter of efficiency, but a crucial financial factor to consider in the production market.

Safety and Compliance Standards

Making certain safety and conformity requirements in the production of copper products is vital to preserving operational integrity and securing both customers and staff members. The manufacturing procedure must follow rigorous regulations stated by companies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Defense Agency (EPA) These policies detail essential safety methods, including appropriate handling of basic materials and waste monitoring, ensuring a safe workplace.

In addition, conformity with industry standards such as ASTM International and ISO qualification is crucial. These companies provide standards that aid manufacturers implement finest methods in top quality control and security steps. Regular audits and inspections should be conducted to make certain adherence to these requirements, as non-compliance can cause unsafe problems and prospective lawful ramifications.

Consumer Trust and Contentment

Depend on and contentment amongst consumers play an essential duty in the success of copper item producers (Copper Products). High-grade copper items not just satisfy rigid market requirements however likewise accomplish customer assumptions, fostering commitment and repeat business. When clients are positive in the top quality of the items they acquire, they are most likely to establish a long-lasting connection with the producer, which can result in referrals and favorable word-of-mouth

To construct this depend on, suppliers have to focus on high quality control throughout the production procedure, making certain that each copper product meets or surpasses specifications. Transparency in manufacturing methods, coupled with click this site commitment to customer care, strengthens the perception of integrity. Furthermore, timely shipment and responsiveness to consumer queries substantially enhance satisfaction degrees.

Customer feedback should be proactively looked for and incorporated into product growth cycles to continually boost offerings. Engaging consumers in discussion concerning their requirements and choices grows a feeling of collaboration, additional strengthening their count on the supplier. Inevitably, a reputation for top quality and customer-centric techniques distinguishes effective copper item makers in an open market, laying the groundwork for enduring consumer partnerships.

Long-lasting Service Success

A supplier's dedication to high quality is integral to attaining lasting company success in the affordable copper products market. Premium items foster consumer loyalty, making sure repeat business and favorable recommendations that drive growth. In a market where dependability and efficiency are vital, business that focus on high quality over cost-cutting actions are a lot more likely to attract attention.

In addition, consistent quality decreases the occurrence of defects and rework, bring about lower operational prices and increased effectiveness. This structured manufacturing procedure allows manufacturers to assign resources properly, enabling financial investments in advancement and technology. Services that adapt to market changes and invest in top quality improvements are better positioned to meet progressing consumer demands.

Additionally, preserving strict high quality criteria improves a business's reputation, drawing in brand-new clients and possible collaborations. A durable online reputation for high quality can work as a differentiator in congested markets, opening doors to lucrative contracts and partnerships.

Ultimately, an unwavering dedication to quality not only guarantees compliance with sector guidelines however additionally grows a lasting organization version. By embedding high quality right into every aspect of the manufacturing process, companies can protect their location as leaders in the copper items market, leading the way for withstanding success.

Conclusion

In check it out verdict, the significance of high quality in copper item production is extremely important. As markets significantly rely on copper for essential applications, keeping rigorous quality control is critical to safeguard an affordable advantage and promote a reputable market visibility.

The importance of high quality in the manufacturing of copper items expands far past mere compliance; it is essential to enhancing efficiency across various markets. In summary, the quality of copper products directly affects their functionality, reliability, and longevity throughout various markets, making it essential for producers to adhere to strenuous high quality control procedures throughout the manufacturing process.

A maker's dedication to helpful resources quality is important to accomplishing long-term service success in the affordable copper items market.